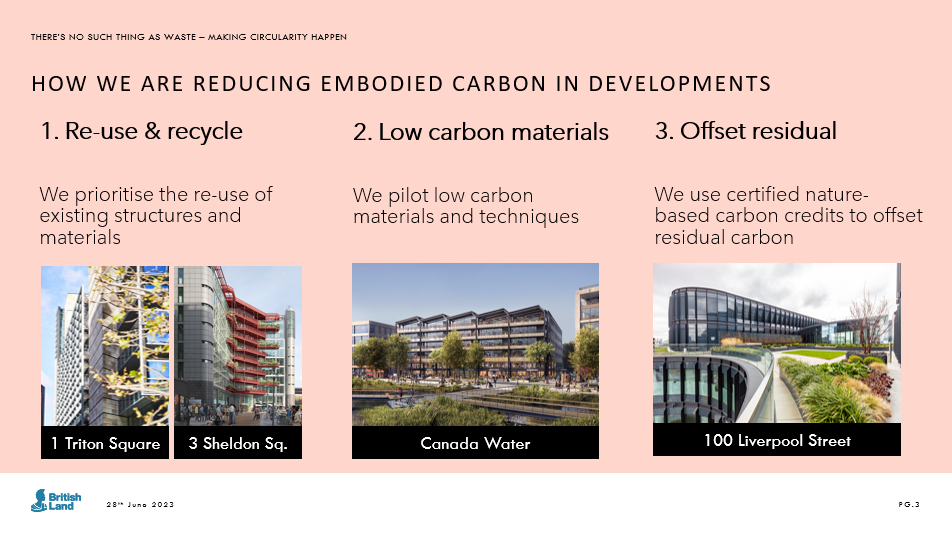

She outlined the idea of ‘buildings as material banks’, whereby existing buildings could become ‘donors’ for recipient buildings in the future. There are now a few examples of where this is being achieved, but there is a need to escalate and accelerate this.

There is a lot of thinking around the material value retention hierarchy, which aims to provide an indicator of the value of reuse and recycling at different levels from retention, down to reuse on site, to reuse off site, recycling on site, and then off site. Reusefully are also working on an EU project looking at the circularity indicators that are helpful at different life cycle stages of a construction project.

The importance of accurate and reliable data pervades just about every stage of this life cycle, and with this in mind, Reusefully are currently working on an Innovate UK funded project to explore the use of AI and image recognition to recognise materials and components in-situ in a building with the goal of accelerating the process of creating material inventories of existing buildings.

There is also a lot of work going on to create standards for circularity, and an EU-level Circular Economy Action Plan, which was originally published for construction in March 2020, with the hope that some of this will still translate into the UK market. The Green Construction Board’s Routemap for Zero Avoidable Waste in Construction provides a valuable tool for understanding the barriers and opportunities in construction circularity and the ASBP (Alliance for Sustainable Building Products) has a number of projects and initiatives such as the DISRUPT toolkit to help scale and promote structural steel reuse, and a Reuse Now campaign to encourage greater reuse.

Lauren Allan is Strategic Development Manager for Revitalite, an organisation dedicated to remanufacturing, taking old light fittings from projects and repurposing them using as much of the original materials as possible. Lauren described how towards the end of last year parent company Synergy were approached to undertake lighting retrofit projects. They are now embracing more circular lighting projects, which includes upgrading old fluorescent lighting to more energy efficient LEDs.

She provided a number of examples of successful installations, but also gave a couple of examples whereby reuse might not always be the best or most cost-effective option. However, in general reconditioned lighting will have cost advantages and, of course, reduce waste and improve energy efficiency. Revitalite are also exploring extended warranties when they repurpose and upgrade lighting systems. They will also test to ensure repurposed systems meet safety standards.

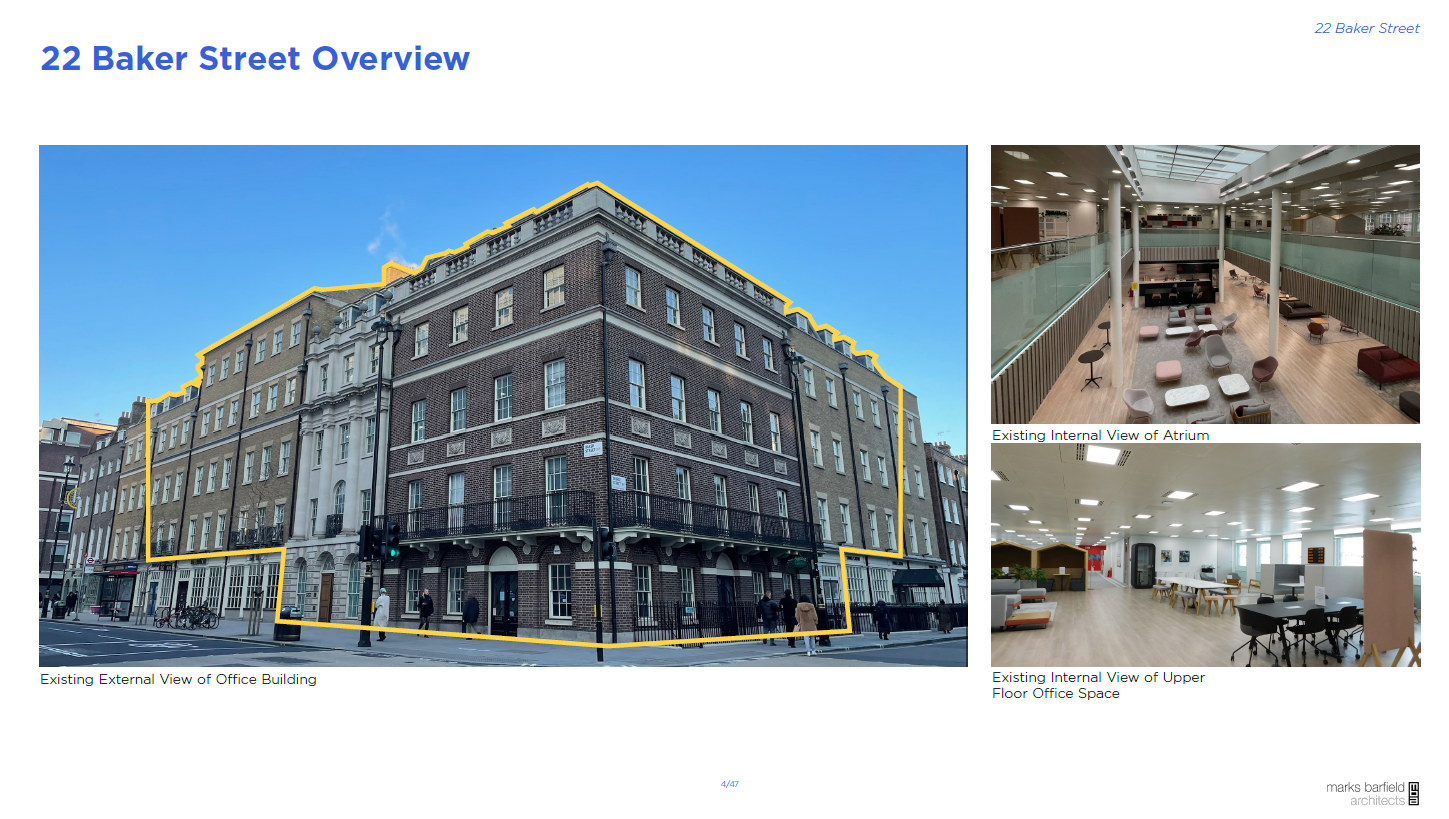

Darcy Arnold-Jones of Marks Barfield Architects described how they are working on circularity projects by using the donor and recipient building concept. They began work on their 22 Baker Street office refurbishment project in 2021, and decided at the start to focus on retrofit and reuse. Three main routes for reuse were curated, with the ideal scenario to reuse materials in-situ, failing this to relocate within the building or donating to a recipient building; a local nearby charity project in Stockwell. This was with a view to avoid downcycling and enable upcycling wherever possible. From their experience, often the term ‘recycling’ in demolition refers to a process of devaluing the existing materials with carbon intensive re-purposing processes.