Ghosts of Christmases Past and Ringing the Bell for 2025!

No, we haven’t turned into Scrooge, although he was an early adopter of resource efficiency.

Gilli Hobbs, co-founder and Director of Reusefully reflects on the year that is coming to an end, and decades of trial and error that can instruct the disruptive thinking and innovation we need to embrace in 2025.

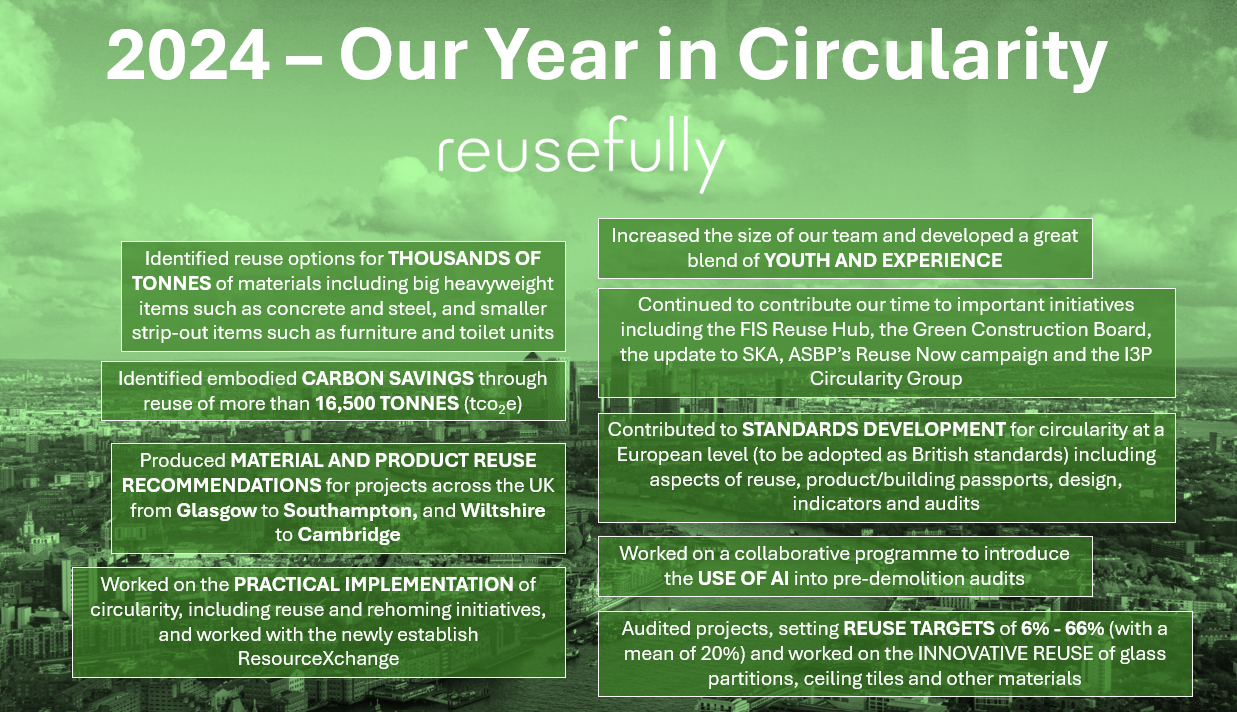

It’s that time of year again when we look back on the year in circularity for Reusefully, and the milestones and achievements of the last twelve months.

We’ve worked on projects up and down the country identifying reuse opportunities in redevelopment and refurbishment projects including offices, schools and university buildings, industrial sites, retail, residential and leisure. We’re particularly proud of our work at 35 Lincoln’s Inn Fields working alongside a fantastic team including David Chipperfield Architects, BDP, contractors McLaren and Deconstruct UK. Overall this year we’ve identified embodied carbon savings of more than 16,500 tonnes through reuse opportunities for the projects we have worked on.

But no SME is an island, and there have been some significant developments in the wider world of circularity, including:

- A tightening of the circularity economy requirements by many London boroughs, with some setting reuse targets of as much as 30%.

- A new regime for construction products regulation for Europe. We may not formally be part of the EU anymore, but developments across Europe will continue to impact the UK - Conference on the new Construction Products Regulation 2024 - European Commission

- Iconic projects and sustainable retrofits such as the Rylands Building are much more commonplace, and a number of commercial developers and asset owners are starting to set more demanding reuse and sustainability targets, for example GPE recently announced 40% for reused materials.

Being a mixture of vintage and young blood, we often reflect on progress made in the past few years in relation to the projects that formed our way of thinking some twenty or so years ago. For example, it’s now over ten years since we got together with other European partners to draft the proposal for the Buildings as Material Banks (BAMB) project – and the concept of buildings as material banks is now common parlance and innovations developed during this project are also embedded into commercial developments today in the form of material passport systems.

Even further back in 1996, we undertook our first pilot Pre-Demolition Audit on the redundant building that preceded

BRE’s Environmental Building. This later led to the adoption on ‘pre-dems’ in certification schemes such as BREEAM and the Code of Practice for Pre-redevelopment Audits, as now referenced in GLA’s Circular Economy Statement Guidance.

Even over the last year, our ‘pre-dems’ have changed from one-off auditing exercises to much more dynamic and iterative projects, working much more closely with the client and design team, and linking through to reuse networks and marketplaces including our partnership with the newly created ResourceXchange who are taking a ‘hands-on’ approach to rehoming materials and products.

Another ‘old timer’ is the Quality Protocol for Recycled Aggregates from Inert Waste, adapted from the output of a pre-2000 Partners in Innovation project which built upon the aforementioned BRE Environmental Building’s incorporation of 100% recycled aggregates in the concrete. Could the development of further protocols and/or standards help accelerate the circular economy transition?

Does this all tell us anything? Maybe..

Firstly, is the importance of innovation. Since our inception three years ago we have been involved in various R&D projects, including research projects looking at wastage rates for different material types, and our current Innovate UK collaborative research project looking to incorporate AI technology into pre-demolition audits.

Secondly, the passage of time, and the evolution of various drivers and technology (such as technology platforms for reuse) means that even if something didn’t succeed in the past, it can be ‘repurposed’ to succeed today. Our experience and the knowledge we have built up over time can help make this success more likely (right place, right time – opportunity knocks!)

Thirdly, and finally, collaboration is key. Being open and transparent, working as a team will yield more low, medium and high hanging fruit. The high hanging fruit is still out of reach most of the time, which brings us back to the need to innovate – it’s all a bit circular after all.